Custom Design – Our Total Home Solution™ Process

Total Home Solution™ is the exclusive process Riverbend has developed to guide you seamlessly through all the stages of your custom-designed timber home project. This overview illustrates the entire process and how Riverbend works with you to create your dream home.

Before You Design Your Home

Before we begin the process of designing your custom home, there are some important factors for you to consider. Finding that perfect piece of land, determining when you want to build your dream home, and, of course, how you intend to finance it. Here are some things to consider in each of these areas as you begin your custom home journey.

Land

We design your home to fit your site and your needs. When searching for land, here are some factors that impact the design of your timber frame home that you may want to consider.

- Topography (slopes, nearby natural features)

- View Corridors (which views do you want to highlight?)

- Size and Shape of Lot

- Sun Patterns

- Location of Neighbors

- Road Access (where your driveway will be located)

Read more about how we design for your lot.

Timeline

Creating your dream home takes time and is a process that you do not want to rush. The process — from design to construction — can vary greatly. Here are some guidelines for your consideration:

2 or More Years Before You Start: Gather ideas and start to develop your design and layout preferences. A lot can change over time, so don’t worry about the details at this point.

1-2 Years Before You Start: If you have not already, now is the time to set an overall budget for the cost of the home, purchase land, and create a list of must-haves and wants for your design.

When You Are Ready to Start: Once you have executed a Design Development Agreement (DDA) with us, the design process begins in earnest. Your Riverbend team works with you to design your timber frame home based on your vision and your budget.

Next Step

Sign Your Design Development Agreement (DDA)

Once you are ready to start the custom design process with Riverbend and have signed a Design Development Agreement (DDA), your design meeting is scheduled. Prior to the meeting:

- Your Riverbend client representative will visit your build site. (The architectural designer assigned to your project can also visit your build site for an additional fee, if you so desire.)

- Provide us with a survey and/or topographical map of your land and build site for our use in designing your home.

- Help us understand your vision for your home by sharing images, sketches, and other ideas you have gathered in your research.

- Your Riverbend team will gather additional information about your property, such as relevant building codes, restrictions, or applicable CC&Rs from your Homeowners’ Association.

Design Meeting

You can choose to travel to our facility or interact directly from home via the web. Either way, you will see the screen come alive as your designer sketches and alters your plan based on your direction. Whether you start with an existing plan or create a custom home from scratch, your Riverbend designer will do more than illustrate, in real time, the changes to your conceptual design. They will also explain how these changes affect your overall design and the whole house cost to build to ensure alignment between your overall budget and desired square footage, architectural styling, layout, and functionality. You will also be introduced to your project manager, who will become your point of contact once the design phase is complete.

Next StepDesign Drawings & Presentation

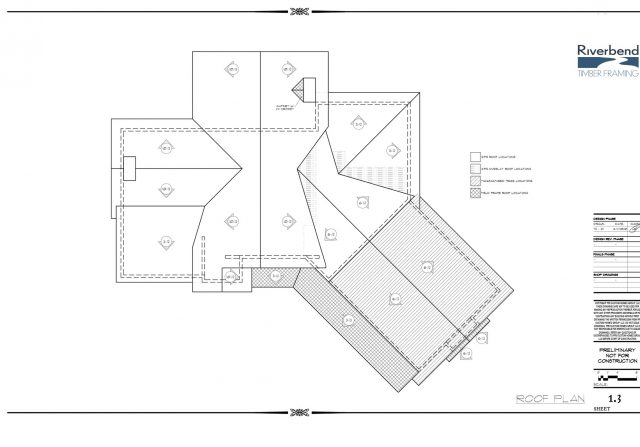

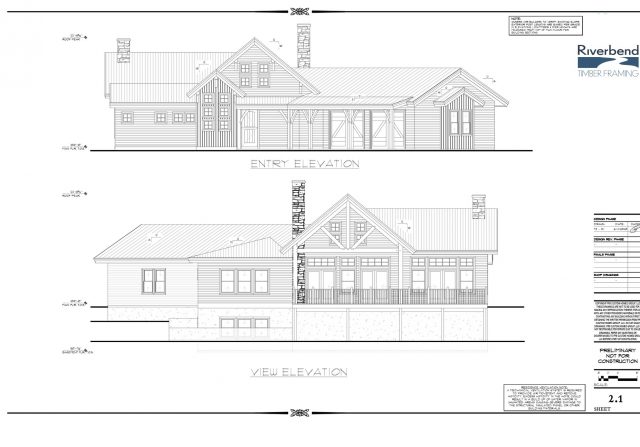

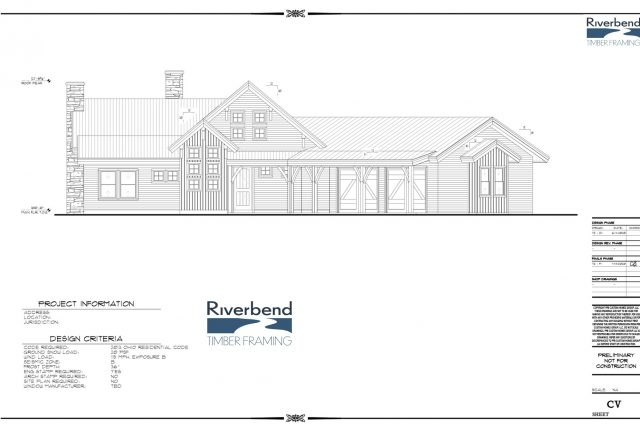

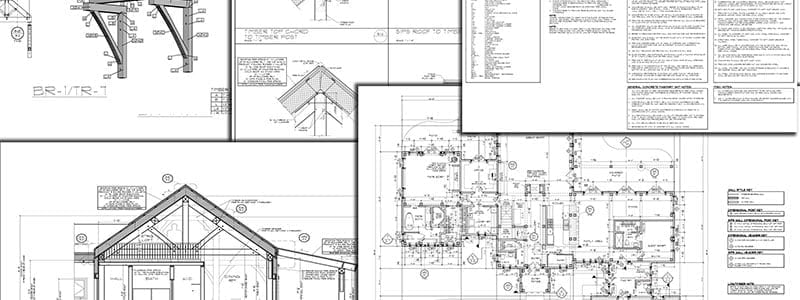

During the weeks following your Design Meeting, your designer will take all your information and sketches to create your conceptual design drawings in AutoCAD, as well as a virtual reality (VR) presentation of your home’s exterior and interior.

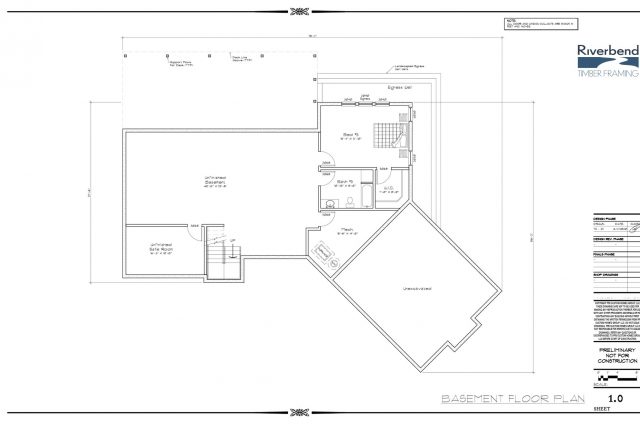

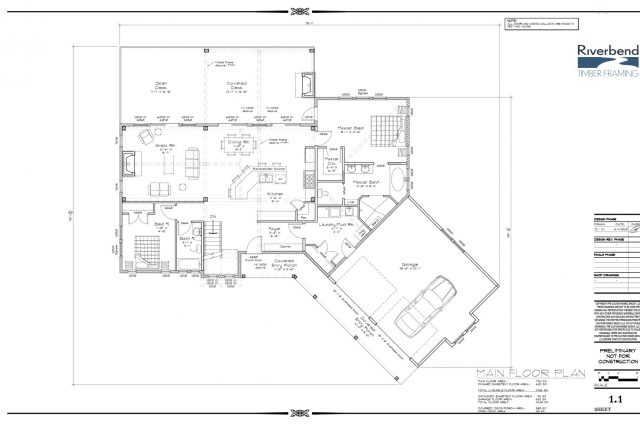

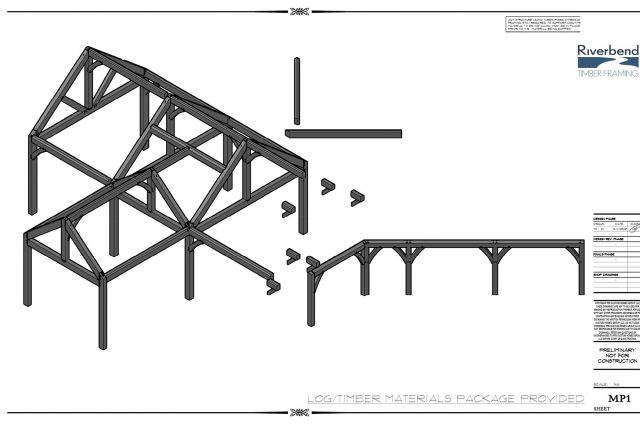

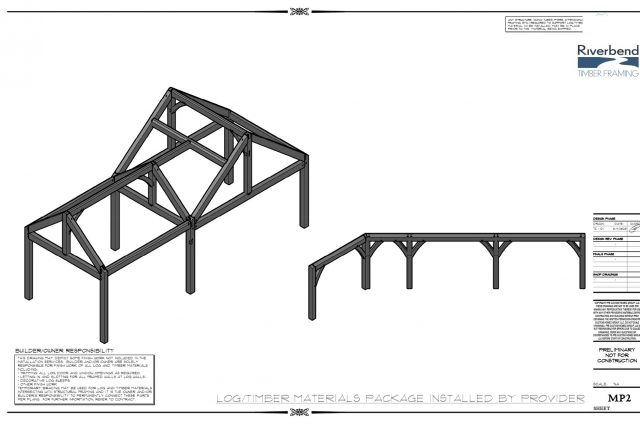

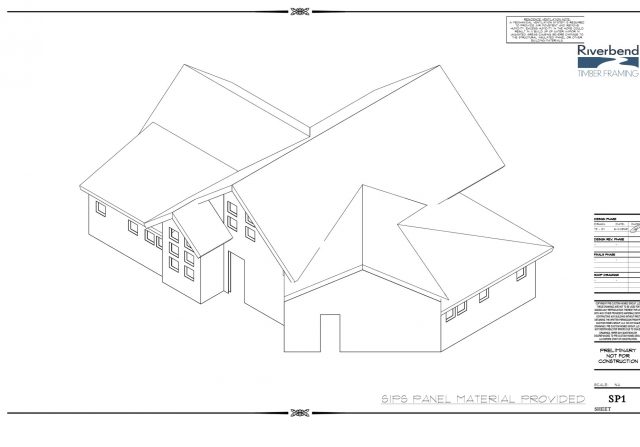

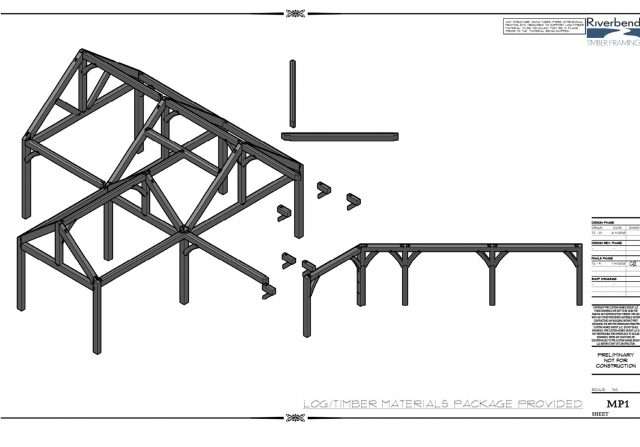

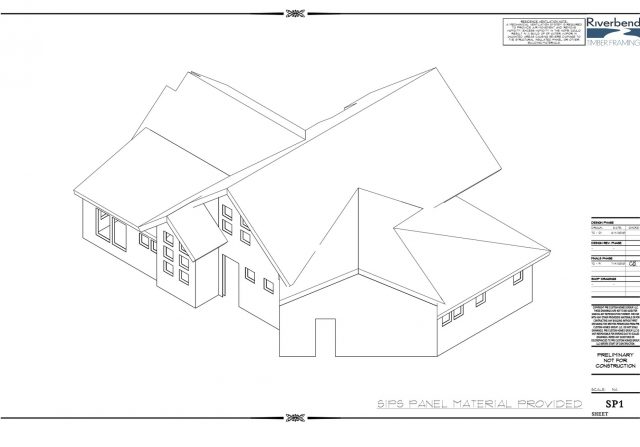

Once complete, your team, led by your designer, will present your conceptual design set and virtual reality (VR) tour of your home to you. The conceptual design set includes detailed floor plans of each level, a 3-D color rendering, and isometric drawings of the timber frame and structural insulated panels (SIPs).

If your design meeting occurs at one of Riverbend’s U.S. offices, you will be able to virtually tour your home in person. If the meeting is done remotely via the web, your designer will present a pre-recorded virtual tour of your home. The VR tour completely immerses you in your new home before you build it.

Custom Design Base Contract

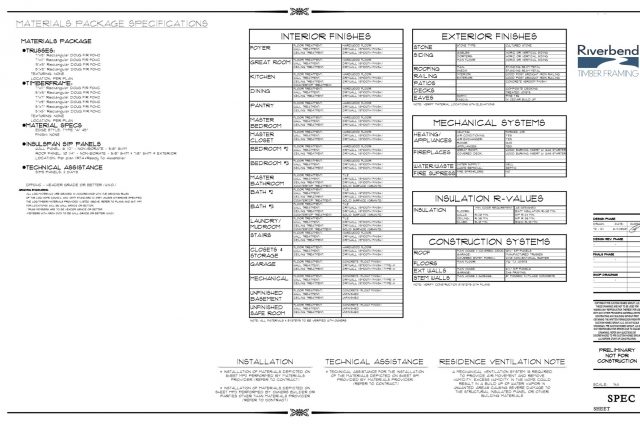

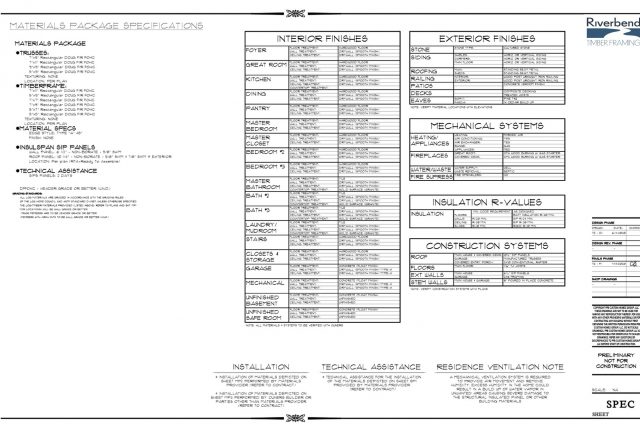

As soon as you are confident that your overall design matches your vision and budget, you execute a Custom Design Base Contract with Riverbend, which includes engineered construction drawings, timbers, structural insulated panels (SIPs), and insulated concrete forms (ICFs).

Next Step

Construction Drawings and Preparing for Construction

After you have signed the Custom Design Base Contract with Riverbend, the preconstruction phase of your project is initiated.

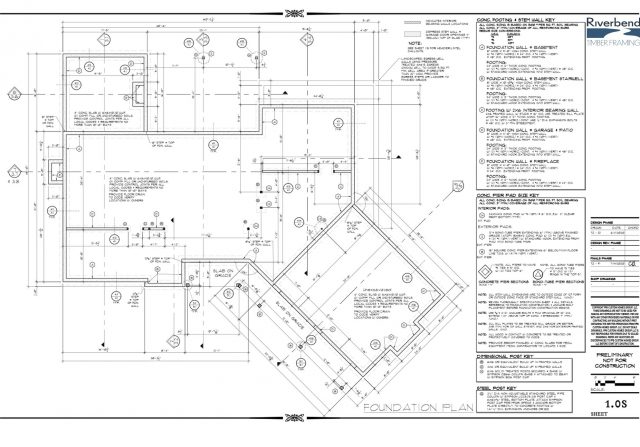

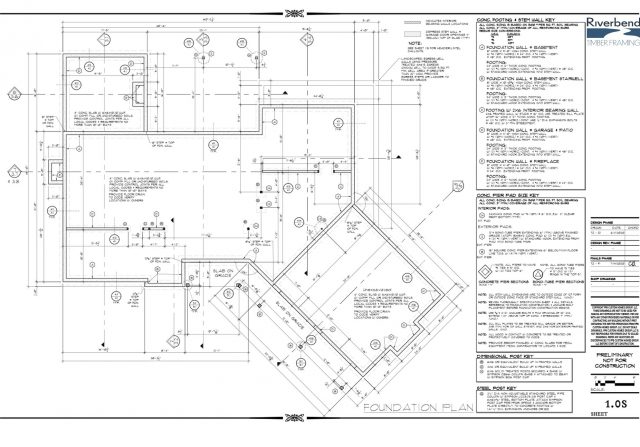

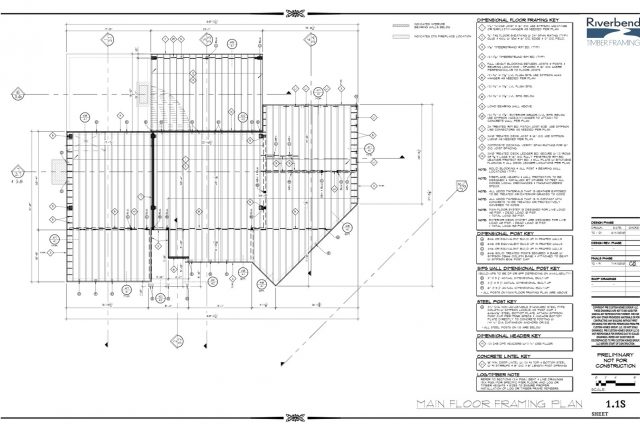

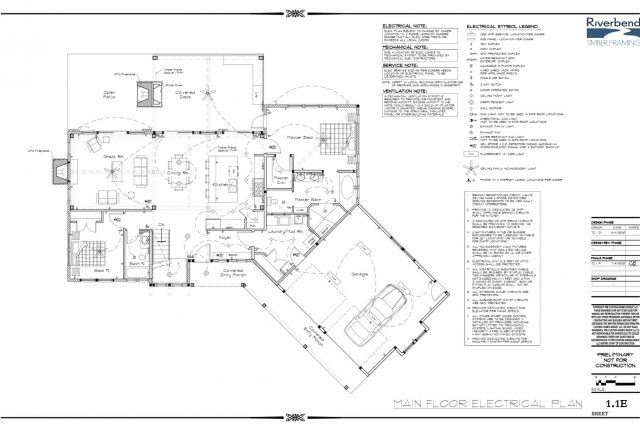

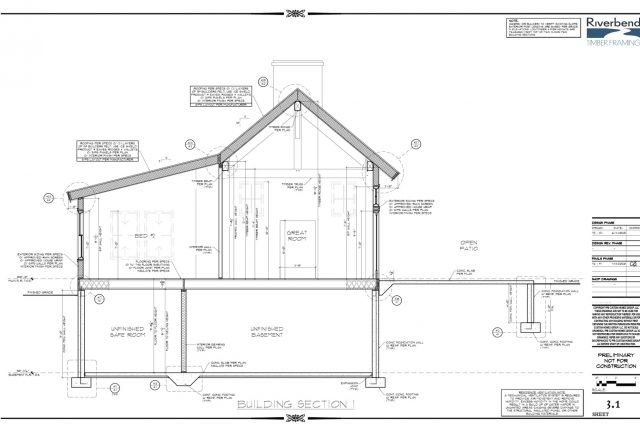

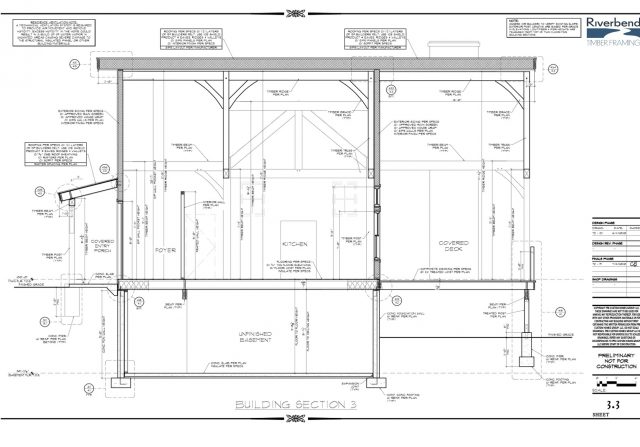

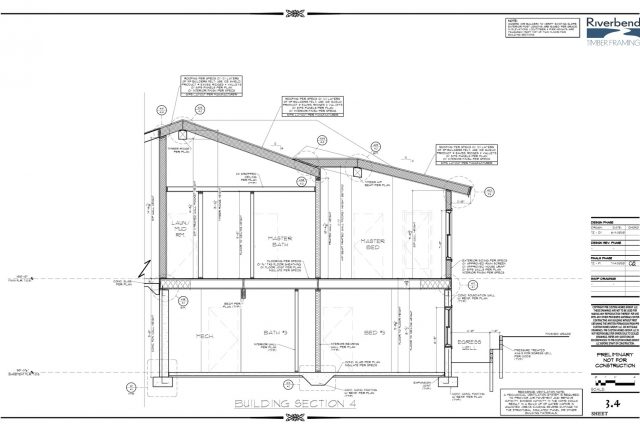

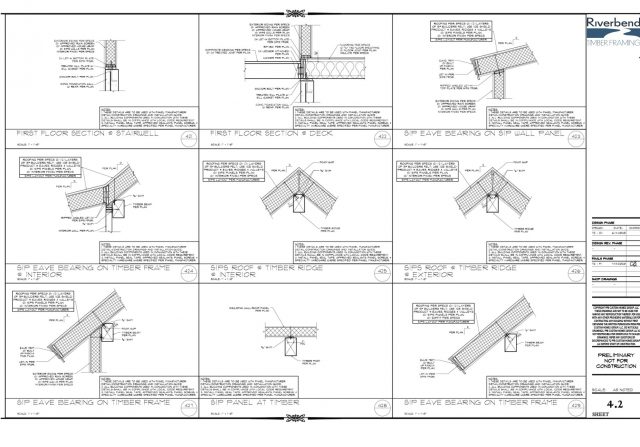

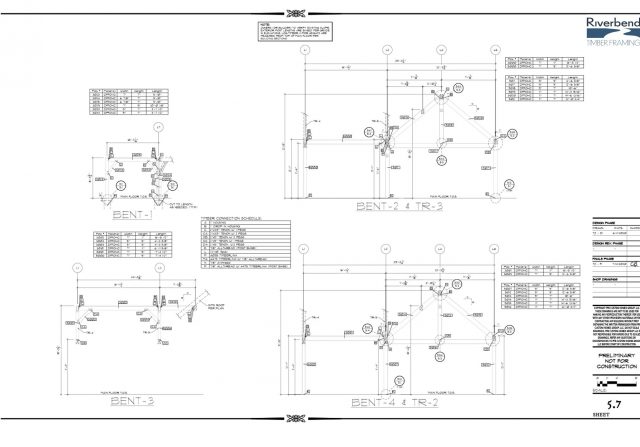

Construction Drawings

At Riverbend, design congruity is very important. The best way to ensure the consistency and quality of your design from concept through construction is to create a full set of detailed, engineered construction drawings. The same Riverbend Design team that drew your conceptual plans will create the construction drawings which will be used by our manufacturing team to fabricate the timbers and SIPs and then by your builder in the construction of the home.

During this phase, the following steps also occur:

- Your Riverbend project manager works with you to select windows, doors, and other materials.

- Riverbend works with a third-party structural engineering firm who reviews and stamps the plans to independently verify the structural integrity of your home.

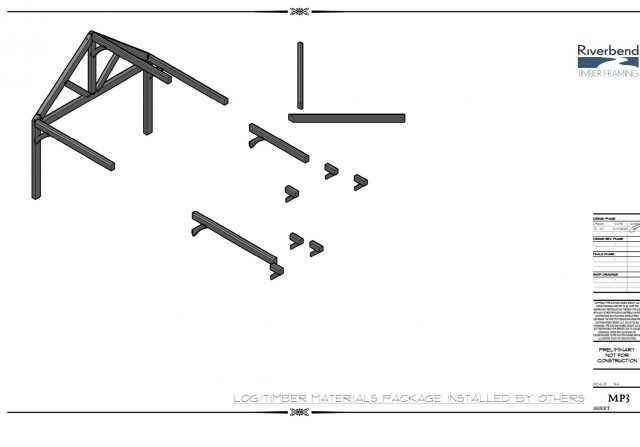

Timber and SIP Fabrication

Manufacturing starts with Riverbend’s fabrication of your timber frame and structural insulated panels (SIPs). During the manufacturing phase:

- The timber frame is fabricated precisely to the specifications set out in the engineered construction drawings.

- The timber frame components are pre-fit at our facility prior to shipping to ensure the highest quality.

- The SIP panels are manufactured at our facility according to the specifications set out in your engineered construction drawings.

Foundation Construction

Meanwhile, at your build site, you and your general contractor will:

- Excavate for your foundation

- Install Riverbend’s Advantage Insulated Concrete Forms (ICFs) — an integral part of Riverbend’s highly energy efficient structural shell

- Pour concrete, backfill, and install the main floor deck, completing the foundation

Installation

After your materials are shipped to your build site, the expert Riverbend crew will arrive and begin the timber frame installation.

Timber Installation

Installation of your timber frame structure by our professional crew ensures:

- The timber frame is erected correctly and as quickly as possible.

- The expert qualification of our installation crews allows problems that arise during installation to be quickly resolved.

- That your builder does not need to be an expert in timber framing in order to build your project, giving you more flexibility in choosing a builder.

On-Site SIP Technical Assistance

Following installation of the timber frame structure, one of Riverbend’s technical advisors works with your builder to install the SIPs. The TA will teach your builder how to properly install SIPs and answer any questions he may have during the installation process. Constructing with SIPs:

- Improves the speed of construction

- Enhances indoor comfort

- Dramatically improves energy efficiency of the home

- Reduces job site waste

If you opt to add Shell Construction onto Riverbend’s Custom Design Base Contract, Riverbend will complete the SIP installation for your builder. Learn more about Riverbend’s Add-On Shell Construction Service in step 9.

Next Step

Construction Solutions Available For Custom Design

Custom Design Base Contract (Fixed Cost)

The Riverbend Custom Design Base Contract includes:

- Engineered Construction Drawings

- Mechanical Energy Evaluation and Drawing Schematic

- Materials including:

– Timber Framing

– Structural Insulated Panels (SIPs)

– Insulated Concrete Forms (ICFs) - Timber Installation

- On-Site Technical Assistance for SIP Installation

Add-On Construction Service Available

Shell Construction (Cost Plus)

Materials and Installation of:

- Structural Insulated Panels (SIPs) Wall and Roof Installation

- Interior Bearing Walls

- House Wrap

Need More Information?

Whether you’re looking for more information or would simply like to learn more about us and our services, don’t hesitate to contact us. Please follow the link below to access our online form or call us at 888.486.2363 in the US or 888.999.4744 in Canada. We look forward to hearing from you.

Order Riverbend Brochure Contact Us